Up to half of a home’s heat can slip out through the attic and other gaps, even in very small living spaces. That surprising fact shows why even tiny openings matter in compact designs.

The main keyword begins this intro and sets the focus on practical, high-value fixes. They will learn which openings matter most: attic hatches, chimneys, windows, doors, recessed lighting, rim joists, ducts, and wall penetrations.

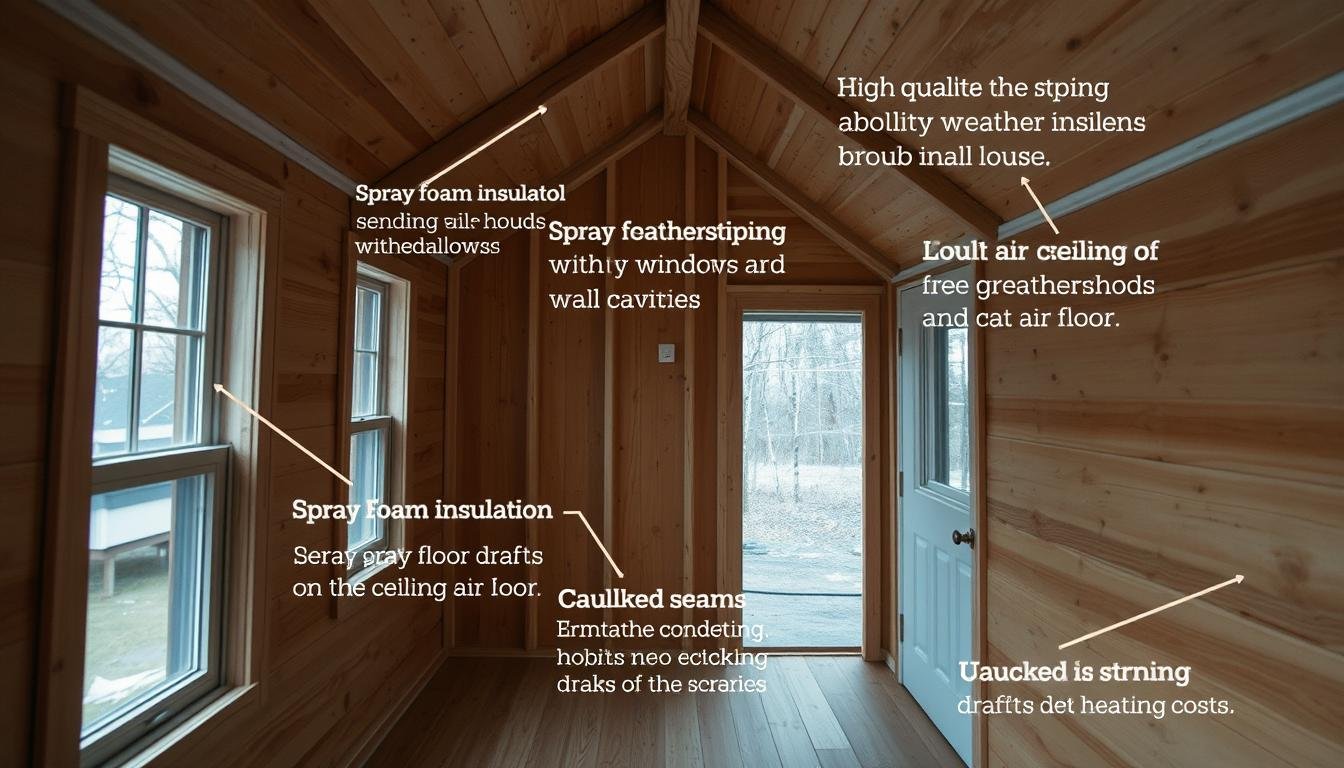

Quick wins like weatherstripping and caulking often pay back in a year or less. Methodical air sealing paired with targeted insulation can cut heating and cooling bills by about 15% on average, and up to 45% in thorough upgrades.

Readers get a clear plan: find the biggest paths first with DIY smoke checks or a blower door, close major gaps at the attic and foundation to stop the stack effect, then add insulation and focused foam at rim joists. For more detail on comprehensive steps and savings, see this definitive guide.

Key Takeaways

- Start with diagnostics: simple smoke or dollar-bill checks reveal major problem spots.

- Prioritize attic and foundation: they deliver the biggest energy wins in small homes.

- Quick fixes first: caulking and weatherstripping yield fast paybacks.

- Pair sealing with insulation: both together boost comfort and efficiency.

- Mind safety and ventilation: install alarms and planned fresh-air paths.

How To Seal Air Leaks In A Tiny House: What To Expect And Why It Matters

A compact living space magnifies the impact of tiny openings on comfort and bills. Excess flow through frames, rim joists, duct penetrations, and the attic often feels like leaving a window open year round.

Proven Savings And Comfort Gains

Controlling air leaks reduces drafts, lowers humidity intrusion, and steadies temperatures. Studies and audits show many homes have exchange rates three to four times higher than needed.

Stopping attic loss cuts the stack effect that pulls cold air through lower gaps. That one move often delivers the largest short-term energy savings and comfort improvement for small footprints.

Air Sealing Plus Insulation: The One-Two Punch

Sealing makes insulation work better. The EPA cites average heating and cooling savings of about 15% when both measures are done together.

- Expect steadier indoor temps, less dust, and quieter rooms.

- Start at attic penetrations, rim joists, then windows and doors.

- A brief audit or blower door test reveals priority gaps and guides limited budgets.

For practical guidance on best practices and safe tightening while keeping fresh airflow, see air sealing your home.

Find The Leaks First: Simple Diagnostics And Pro Tools

Pinpointing problem spots saves time and delivers the biggest comfort gains fast. A short, methodical inspection reveals where drafts and wasted heat escape. Documenting each location helps plan work that yields the best energy returns.

Blower Door And Thermal Imaging Basics

A blower door depressurizes the room with a fan in the doorway. This forces outside air through gaps, making hidden paths visible. Pros often pair the test with thermal imaging to map temperature differences across surfaces and locate stealthy leaks.

DIY Pressurization Test With Incense Or Smoke Pencil

On a windy day, shut off combustion appliances and close openings. Run an exhaust fan to pull air out and move an incense stick or smoke pencil near suspect seams. Follow the smoke—steady pulls mark problem spots.

Flashlight, Dollar-Bill, And Visual Clues

At night, use a flashlight to spot light showing through gaps. The dollar-bill test checks weatherstripping at windows and doors. Look for dusty insulation, frost in winter, or dust trails near penetrations as clues.

Common Leak Paths In Tiny Homes

Check attic hatches, recessed lights, chimneys, plumbing and wiring penetrations, duct seams, rim joists, window frames, and the foundation first. Prioritize the biggest openings and record severity so the largest leaks are sealed early for fastest savings.

Further reading: see this guide and a detailed post for step-by-step diagnostics.

Gear Up: Materials, Safety, And Indoor Air Quality

Gathered materials and a clear safety plan make the project faster and less messy.

Essential Air Sealing Materials For Small-Space Projects

Keep the kit compact. Silicone or acrylic‑latex caulk handles small stationary cracks. Compressible weatherstripping fits operable sashes and doors.

Use low‑expansion spray foam for larger penetrations without bowing frames. For ducts, choose foil tape for quick joints and brush‑on mastic for long‑lasting seals.

Aluminum flashing with high‑temperature sealant is required around flues. Add outlet gaskets, backer rod, and chimney balloons for unused flues.

Personal Protective Equipment And CO/Smoke Alarms

Wear eye protection, gloves, and disposable coveralls. A dust mask is essential in attics and crawl spaces. Keep a flashlight and test CO and smoke alarms before starting.

Ventilation Considerations To Avoid Over‑Tightening

Controlled ventilation matters. Reduce uncontrolled leakage but maintain planned vents so indoor air and moisture stay balanced.

“Seal smart: pair tightening with fresh‑air strategies to protect health and energy savings.”

- Stage tools: caulk gun, foam can, gasket kits, and chimney gear.

- Plan laydown areas and protect finishes to minimize mess.

- Note cure times and water cleanup for each product before reuse.

Seal Windows And Doors For Immediate Draft Reduction

Drafts at doors and frames often account for the fastest, cheapest comfort gains in small homes. Targeting these openings gives quick results and lessens the stack effect that pulls cold air up through the attic.

Caulking, Weatherstripping, And Door Sweeps That Work

Caulk fills joints under about one inch between stationary components like window frames and trim. Use backer rod plus caulk for wider cracks; the rod supports a neat bead and durable finish.

Adhesive-backed foam and V‑seal or bulb profiles fit moving sashes and exterior doors. Replace worn strips and check hinges and strike plates so compression across the seal is even.

Door sweeps and threshold gaskets stop cold air at the bottom of doors. Add draft stoppers where layout allows for extra protection without changing thresholds.

- Use low‑expansion spray foam around jambs for larger voids; it will not warp frames when applied sparingly.

- Reapply weatherstripping at high‑traffic doors on a seasonal schedule; loose seals are common wear points.

- Install foam gaskets behind outlet plates on exterior walls to cut drafts.

“A quick dollar‑bill or flashlight check reveals places that need immediate attention.”

| Task | Best Material | When To Use |

|---|---|---|

| Perimeter gaps under 1″ | Silicone or acrylic‑latex caulk | Window frames, trim seams |

| Operable sashes and doors | Adhesive foam, V‑seal, bulb weatherstrip | Replace worn strips, seasonal checks |

| Threshold and bottom leaks | Door sweep, threshold gasket | Exterior doors, sliding units |

| Behind trim voids | Low‑expansion spray foam | Large cavities, around jambs |

Verify performance with a dollar‑bill test and a flashlight check at night. Small fixes here yield quick comfort gains and reduce the pull that makes attic losses worse.

Prioritize The Attic And Ceiling Plane In Tiny Houses

The attic plane often acts like the lungs of a small dwelling, driving drafts and heat loss unless it is given priority.

Stop The Stack Effect With Targeted Attic Air Sealing

Start at the attic floor. Locate wiring, plumbing, and top-plate penetrations and use caulk for narrow gaps and low-expansion foam for larger voids. Methodical work here reduces the suction that drags cold air through windows and doors.

Safe Seals Around Flues, Recessed Lights, And Chimneys

Cap recessed fixtures with code-compliant fire-retardant covers and seal edges carefully. Flashing and high-temperature sealant belong around furnace flues, water heater vents, and chimneys.

“Protect thermal barriers and safety clearances while closing openings.”

Pair With Attic Insulation For Maximum Efficiency

Air sealing and insulation work together. After closures are complete, add or top up attic insulation to recommended levels. This step locks in energy savings, lowers moisture risk, and helps prevent ice dams in winter.

- Weatherstrip and insulate the attic hatch—often an overlooked loss point.

- Verify results with a smoke pencil or during a blower door test.

- Treat loft ceilings as the same critical barrier and keep clearances around hot surfaces.

For comprehensive guidance on comprehensive leakage control and recommended practices, see attic air leakage control.

Close Foundation, Floor, And Rim Joist Gaps

Where framing meets foundation, even narrow cavities can undermine comfort and invite moisture. This zone often pumps outside air under the floor and through rim joists, increasing dust and energy losses.

Seal And Insulate Rim Joists In Small Footprints

Inspect the rim joist perimeter carefully. Use silicone caulk for hairline cracks at sill plates and low‑expansion spray foam for larger cavities. After the seal cures, add rigid foam or fiberglass batts for thermal performance.

Fix Wall, Penetration, And Subfloor Openings

Fill plumbing, electrical, and vent penetrations with backer rod and appropriate sealants for clean, durable joints. For concrete foundation cracks, apply silicone for small cracks and repair mortar for stone‑and‑mortar walls where foam would fail.

“Stopping gaps at the floor line reduces drafts, moisture intrusion, and dust migration into living spaces.”

- Prioritize rim joists where drafts are noticeable.

- Match material: caulk for small cracks; foam for cavities; mortar for masonry repairs.

- Finish with a smoke pencil or blower door pass to confirm results.

| Location | Recommended Material | Why It Matters |

|---|---|---|

| Rim joist perimeter | Low‑expansion spray foam, caulk | Stops major floor‑level drafts and reduces energy loss |

| Subfloor penetrations | Backer rod + silicone or foam | Prevents dust and moisture entry around pipes and wires |

| Concrete cracks | Silicone caulk or concrete repair mortar | Durable fix for water and air pathways |

Don’t Forget Ducts, Vents, And Penetrations

Ductwork and utility penetrations quietly bleed conditioned air and cut system performance when left unchecked. Small runs, tight chases, and hidden takeoffs often hide gaps that reduce comfort and raise energy bills.

Foil Tape, Mastic, And When To Call Pros

DIY first steps: Inspect seams, elbows, takeoffs, and the air handler connection. Use UL-rated foil tape at seams and a brush-on mastic for longer-lasting joints.

Wrap exposed runs with insulation after sealing. For dryer vents, clear lint and confirm terminations face outdoors; this saves energy and cuts fire risk.

When pros are needed: Technicians can apply aerosolized sealant or liquid rubber from inside ducts to reach hidden openings behind walls and in tight chases. That method is effective where manual access is limited.

- Seal bath fans, kitchen vents, and plumbing penetrations with caulk or low‑expansion foam.

- Verify backdraft dampers and external terminations work correctly.

- Use targeted weatherstripping on worn windows and doors as a cost‑effective upgrade.

“Fixing ducts and penetrations supports the attic and floor air barrier and amplifies other upgrades.”

For product guidance on foam and joint prep, see this insulation and foam guide.

Budget, Timeline, And Rebates In The United States

Knowing likely costs and available rebates makes project planning far less stressful. Owners can plan a realistic timeline and spot programs that lower out‑of‑pocket expense.

Typical Project Costs And What Affects Them

Comprehensive home air sealing and insulation projects typically range from $5,000 to $12,000 when done properly.

Costs vary by home size, access to the attic and foundation, number of penetrations, and required finish repairs.

- Accessible attics and easy window work lower labor hours.

- Hard-to-reach foundation or exterior cavities push a project into the higher band.

- Quality materials and licensed crews increase upfront cost but often boost long‑term savings.

Rebates, Weatherization Programs, And Energy Audits

A certified home energy audit — usually including blower door testing and thermal imaging — directs spending toward the biggest leaks and cracks first.

Bundling air sealing with attic insulation commonly unlocks utility rebates and weatherization assistance. Many state and local programs offer rebates, financing, or free audits that lower initial investment.

“Document before/after blower door numbers and photos to qualify for incentives.”

| Action | Typical Timeline | Notes |

|---|---|---|

| Windows and door weatherstrips | Weekend (DIY) | Fast savings, low cost |

| Attic and rim joist work | One pro day or several DIY sessions | Often prioritized by programs |

| Whole‑home audit and upgrades | 1–4 weeks | May qualify for rebates or low‑interest loans |

Tip: Vet contractors for Building Performance Institute credentials and ask that proposals include both air sealing and attic insulation where needed. That way, program rules and savings align with the work performed.

Conclusion

Targeting top and bottom leakage first stabilizes comfort and cuts drafts at windows and doors. Closing attic and foundation paths delivers the fastest wins for energy and moisture control.

Core tools include caulk, weatherstripping, gaskets, low‑expansion foam, mastic, and proper flashing. Used correctly, these materials fix common gaps and cracks around windows, doors, and penetrations.

Pairing air sealing with added insulation locks in savings and reduces winter heat loss. Verify results with simple smoke tests or a blower door reading after work is done.

Plan for controlled ventilation, test CO and smoke alarms, and check rebates or audits for cost help. For practical guidance on overall efficiency and incentives see sealing air leaks and an energy‑efficient layout approach.

FAQ

What savings can one expect after proper air sealing and insulation?

Proper work often cuts heating and cooling bills by up to 30% for small-footprint dwellings. Savings vary with climate, existing insulation, and HVAC efficiency. A targeted air-sealing job reduces drafts, lowers run time for heaters and air conditioners, and improves overall comfort.

Which diagnostic tools reveal the most hidden gaps?

A blower door test and thermal imaging camera give the clearest picture of leakage. For DIY checks, a smoke pencil or incense, a simple pressurization test with a fan, and visual inspection using a flashlight and thin smoke will find many problem spots.

What common leak paths should be inspected first?

Inspect window and door frames, rim joists, attic hatches, recessed lights, plumbing and electrical penetrations, vents, and gaps around chimneys or flues. These areas account for the majority of uncontrolled airflow in compact homes.

Which materials work best for small-space projects?

Use low-expansion spray polyurethane foam for odd-shaped gaps, high-quality silicone or polyurethane caulk for stationary joints, and adhesive-backed weatherstripping for operable windows and doors. Foil tape and mastic seal duct connections effectively.

Is there a risk of indoor air quality problems from over-tightening?

Yes. Excessive tightening without proper ventilation can concentrate pollutants and moisture. Maintain mechanical ventilation such as an ERV/HRV or ensure adequate exhaust fans. Install carbon-monoxide and smoke detectors when combustion appliances are present.

How should windows and doors be treated for immediate draft control?

Apply high-quality weatherstripping around operable frames, replace failing door sweeps, and caulk stationary trim gaps. For older windows, consider storm windows or thermal curtains as interim solutions while planning upgrades.

Why is the attic plane a priority in small homes?

Warm air rises and escapes through ceiling and attic gaps, driving the stack effect. Sealing attic penetrations and adding insulation at the ceiling plane stops most heat loss and greatly reduces heating loads.

How are flues and recessed lights sealed safely?

Use fire-rated sealants and firestop materials around chimneys and recessed fixtures. Keep required clearances for combustion vents and use sealed, IC-rated recessed cans. When in doubt, consult a licensed contractor to ensure code compliance.

What about rim joists and floor gaps on trailers or foundations?

Insulate and seal rim joists with closed-cell spray foam or rigid foam board plus caulk. Seal gaps at the sill plate and any subfloor penetrations; on raised foundations, block wind wash with continuous insulation and vent screening where required.

Should ducts and vents in compact systems be sealed?

Yes. Seal duct joints with mastic or UL-rated foil tape and insulate exposed runs. Even small leakage percentages waste significant conditioned air in compact systems and reduce comfort and efficiency.

When is professional help recommended?

Hire pros for blower door diagnostics, complex ductwork, combustion appliance leads, structural penetrations, or when fire-rated sealing is needed. Contractors also help with rebate paperwork and comprehensive weatherization programs.

What typical costs and timelines apply for a DIY versus pro job?

A DIY materials-only retrofit can cost a few hundred dollars and take a weekend or two, depending on scope. Professional air-sealing plus diagnostic testing usually runs from several hundred to several thousand dollars and may take a day or two for a small dwelling.

Are there rebates or programs in the United States that offset costs?

Yes. Many utilities, state energy offices, and federal weatherization programs offer rebates, tax credits, or low-cost audits. Check the Database of State Incentives for Renewables & Efficiency (DSIRE) and local utility websites for eligibility and application details.